This Is One Man’s Idea Of A Relaxing Hobby In Retirement.

Imagine this, you retire, then become interested in hobby metal casting, later, a deep interest is developed in the bronze cast works of the ancient Etruscan civilisation. (The Etruscans preceded the Roman Empire)

At a much later date, you decide to show your cast bronze Etruscan horse reproduction sample to the British Museum… they accept your work, and the Museum then commission more of the same!

Peter Cottam from the UK says that, “This is only the second thing I have ever cast, the first being an Egyptian cat. I still have a huge amount to learn about the technique, and I can’t help thinking that this has all come just a little bit too soon for comfort”

Before I retired, I was an Electro/Mechanical Engineer, so I wanted a hobby that would combine lots of different skills. This was supposed to be my idea of a relaxing hobby in my retirement, what have I done?

Peter, as you will learn, has achieved some remarkable results and success with his hobby metal casting, so much so, that his magnificent Etruscan Bronze cast horse are being sold in the London museum.

This is an enviable and quite remarkable achievement when you consider the high standard requirements of the British museum.

We congratulate Peter on his grand achievement, I think we could honestly say that here is one very quiet achiever.

Below, Peter will walk you through the process in pictures and text the process he employs to create his magnificent bronze castings.

In the email to me, Peter says; “This is basically a step-by-step record of how I made the bronze horse using the lost wax process”.

There are about sixteen photographs that illustrate the entire process, but of course, it takes a lot of experimenting, and trial an error to arrive at a point where you are happy with the results… and well, here they are.

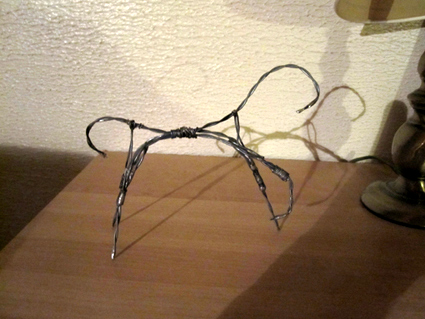

The wire frame is the core, support or backbone of the model, the next photo will help to explain that more.

Clay is added then carved and formed into the final form and shape required.

The clay model is covered in RTV rubber material. Then a supporting mould of plaster is constructed, an important feature is where the plaster mould parting line is made, so that it can be separated after setting.

If Peter, after a lot of hard work, can make a success of metal casting, then you can too.

Lost wax casting is a lot more complex process than green or silicate sand casting, it requires a higher skill level, and most of all, extreme patience, but the results and quality as displayed are exceptional, enough to be in demand by the British Museum.